Click on a photo to enlarge it.

We headed towards a Bourbon distillery to go on a tour but the road was blocked due to an accident. It must have only just happened. We could only

see one of the cars involved which was upside down on its roof.

We had to turn around and gave up on that particular distillery because the detour we would have had to make to get there was too long. So we went

to a library instead and then drove to Frankfort, the capital of Kentucky.

The State Capitol building is very impressive with its marble Greek columns and two upper floors. Helen was Speaker of the House, albeit without an

audience - they got bored!! She also had the chance to become the Chief Justice. What a busy woman!

The next day we celebrated Helen's new jobs by going to Buffalo Trace distillery for a well earned Bourbon! It is the oldest continually running

distillery in the US (1857). Bourbon is made from corn, barley, yeast, and either wheat or rye, plus the limestone rich water of Kentucky. The

higher the percentage of corn, the smoother the bourbon is. It is aged for a minimum of 4 years in virgin oak barrels taken from the middle third

of the tree trunk. The barrels are only used once for bourbon which can be aged up to 23 years.

After 23 years of aging, the original 53 gallons in a barrel have evaporated down to 7 gallons - hence it costs $450 a bottle!! In May 2008, they

filled barrel number 6 million which was rolled off the assembly line by our tour guide's 92 year old father who has rolled off all the other

"million" mile marker barrels and was worried if they didn't hurry with the production he might not be around for this one!

After the tour we had a tasting of 40% vodka, and two bourbons. They tasted really bad but then we are not exactly connoisseurs!! The bourbon ball

chocolates were more in line with our tastes!

We also took a look at a mural that depicts a walkway between barrels and moves with you when you walk past.

The next day we went on a completely different tour - to the Toyota manufacturing plant in Georgetown. What a super tour. If you are ever this way

then you have to see it - it is fascinating.

We were given protective glasses and headsets and ridden around the plant on a trolley with a tour guide. Production starts with huge steel rolls

weighing up to 24 tons and delivered every 30 minutes by trucks. They are then unloaded by cranes and lifted into the stamping machines which are

very noisy.

The steel is stamped using 200 different moulds for the various parts. Toyota also makes their own plastic parts. We were not allowed into the

paint shops due to the dust and lint free environments.

It takes 20 hours for one vehicle to be made - they make the Camry, Solara, Avalon and from next year the new Venza which they were already making

prototypes for.

Everything is tested. They even cut open every 20th engine, thereby ruining it, to make sure everything has been made correctly. Workers have

moving seats, lie down stools and hydraulic chairs and change jobs every 2 hours to use other sets of muscles and avoid muscle fatigue.

There are 700 automated machines, and there are 44,000 welding operations per car. Self-guiding automated vehicles move along the floor to transport

things from one place of the massive assembly areas to another. They follow magnets along the floor and it is really odd watching these things glide

along.

The whole atmosphere seems to be out of a sci-fi movie. There is so much to see and too much to listen to because the guide is telling you all the

facts and figures whilst you are traveling along. Totally amazing.

Unfortunately no photos or video was allowed and Kirsten had to take photos of photos that were on view in the foyer. So you'll just have to go on

a tour!

The plant was opened in 1988 and has made 6 million cars. It is 7.5 million square feet in size and there are 7,100 employees called team members

and 2-3,000 contractors. Only 1% is Japanese, and 96% are from Kentucky. 22% are women. There is a great benefits package and they give away free

cars every year. We were seriously considering asking for a job!!

The next day we drove into West Virginia and managed to exchange some of the books that we had read and were carrying around with us. We also drove

around looking for a campground that was supposedly only $7 a night for full hook up but turned out to be $20. Then we made it to Wal-Mart. We were

exhausted even though we hadn't done much!

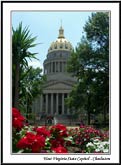

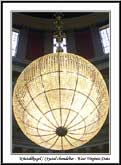

Our next stop was the State Capitol building in Charleston where we went on a free guided tour for one hour and saw the Senate and the House of

Representatives. We marveled at all the huge chandeliers. The largest is 8 feet in diameter, has 10,080 crystals and 96 bulbs. It has to be

hand-cranked down every 4 years to be cleaned. It takes 3.5 hours to bring the chandelier down and 4.5 hours to get it back up.

We also met Danny Wells who is a house representative and was giving a tour for some friends, which meant that we got to see some rooms that are

normally off limits!